Get in Touch With Me

FREQUENTLY ASKED QUESTIONS

Raw dice are straight from the mold. They are untouched by sanding or polishing. They may have slight rough edges on the lowest face and occasional scuffs from the molding process. Perfect for those who wish to finish them to their own preference.

I use a pressure pot, which is different from a pressure cooker or vacuum chamber. It’s a specialized pot that applies very high pressure, specifically designed for resin casting. This pressure forces the bubbles to shrink so small that they essentially disappear.

A standard 8-piece finished polyhedral dice set is currently priced at €90, though this may vary based on design complexity and material costs. A raw dice set typically costs around €40.

Additionally, there are special high-quality presentation sets, including a 13-piece polyhedral set for around €150 and a Yamb dice set for around €50.

Commission ranges from around €100 for Yamb, through €170 for an 8-piece set in a bag, all the way to around €250 for a 13-piece dice set in a presentational box. The price can differ depending on the agreed-upon technique requested.

Commission is a process where you are the main designer and everything is created for your taste!

You’re choosing a theme for the dice. You can explain your character, object, or someone’s favorite colors, and we can work from there. You can choose the color of the numbers, a specific inside design, what to add to the dice, or a specific technique.

You’re in charge of the color of the numbers and the entire process of dice design.

The most important part is that we’re working on the dice and making it until you’re satisfied and give us the green light.

Handmade dice are crafted with meticulous attention to detail, which is the primary reason behind their higher cost compared to mass-produced dice. This is a general overview of the process involved in making dice:

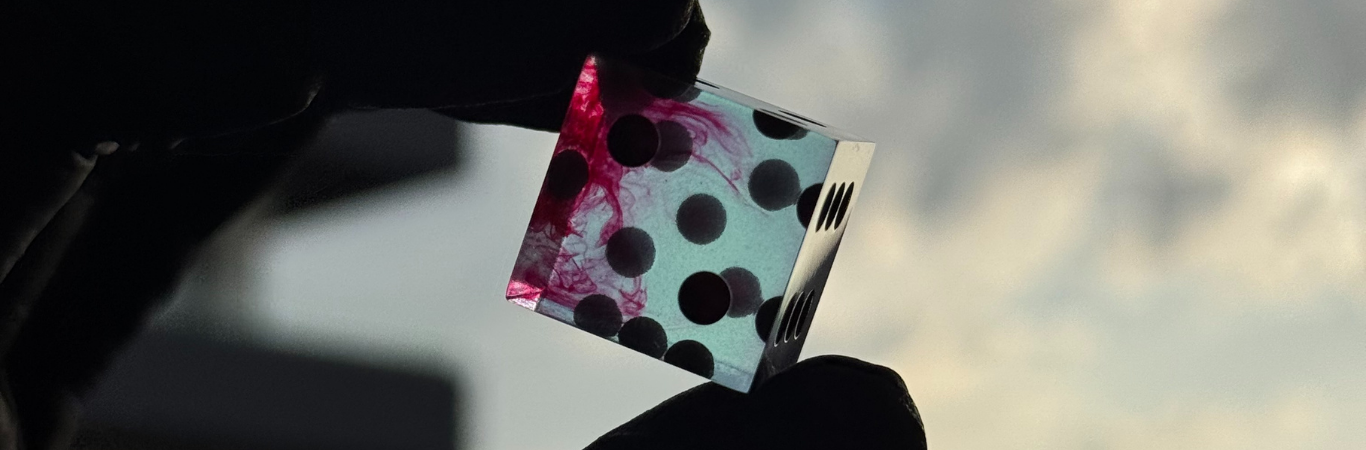

It begins with 3D modeling the dice (master), designing supports, and 3D printing the prototype. The master is then sanded and polished before creating a mold. Once the mold is ready, the resin is carefully poured, incorporating design elements like liquid cores if needed. After curing, the dice are sanded, polished, and finally inked to complete the process. Each step demands precision, patience, and craftsmanship to produce high-quality, unique dice.

And to top it all off, I personally handle every single step of the entire process, ensuring the highest quality and attention to detail in every die I create.

I make my own molds.

I use multiple resins, primarily high-viscosity ones with a 1:2 mixing ratio, but sometimes I use lower-viscosity ones to use for some specific techniques.

Handmade dice are much more balanced than factory-made ones. The randomness of your rolls is influenced more by how you throw them than by their balance. None of my dice are weighted, and the pigments, colorants, or inclusions I use don’t affect their weight. Inclusions are typically made from resin or materials with similar density, so they won’t throw off the balance.